The manufacture of coins, or minting, began in Britain around the end of the second century BC. At this time, coins were cast in moulds, but later they were struck by hand in a process that would continue to be used for the next 1,500 years.

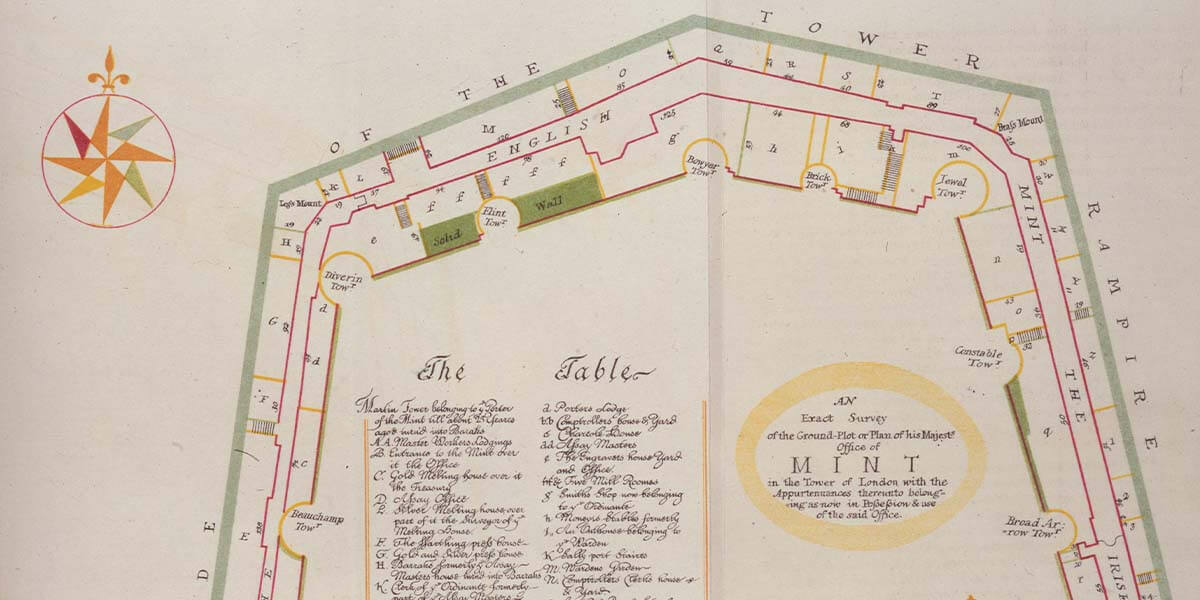

It was not until after the Romans had left Britain that a London mint was in regular operation. Its beginnings, circa AD 650, seem to have been quite unstable, but from around the time of King Alfred the Great (r. AD 871-899) its history became continuous. By the Battle of Hastings in 1066, the number of mints had declined and from the early part of the thirteenth century, minting was mainly confined to London and Canterbury. By about 1279, minting had moved to more secure quarters within the Tower of London.

For the next 500 years, The Royal Mint remained in the Tower of London. By 1701, the buildings were described as ‘largely of wood; the chief of them were two storeys; most were crazy with age, held up by timber shores and pinned together with clamps of iron’. Minting processes were finally mechanised in the seventeenth century. The use of mills and presses improved the appearance of the coins and made them more difficult to clip and counterfeit, but it also highlighted the cramped conditions in the Tower.

During the Napoleonic Wars, the demands of the garrison, coupled with the difficulty of accommodating new steam-powered machinery, led at last to a decision for the Mint to leave the confines of the Tower in 1810. The site chosen for the new Royal Mint was on nearby Tower Hill, in an area recently occupied by tobacco warehouses.

In the 1880s, the factory buildings were reconstructed and extended, with new coining presses being installed and melting and rolling capacity increased. Steam gave way to electricity and the work of construction and renovation became a continuous process as The Royal Mint attempted to cope with an enormous increase in the demand for coin at home and overseas.

Once the implementation of decimalisation was set for 15 February 1971 it was quickly noted that the Tower Hill site wasn’t large enough to produce the hundreds of millions of coins needed for the change in the British coinage system, while still keeping up with The Royal Mint’s overseas commitments. The solution was to rebuild The Royal Mint at a new location that could accommodate the increased workload. In 1967, it was announced that a new Royal Mint would be built at Llantrisant in South Wales, ten miles north of Cardiff, in line with government policy of transferring industry from the capital to areas in need of development.

Once the initial requirement for decimal coins had been satisfied, production was transferred from Tower Hill to Llantrisant. A second phase of development was commissioned in 1975 and, with the new mint capable of the full range of minting activity, the last coin, a gold Sovereign, was struck in London in November of that year. The Tower Hill buildings were finally closed in 1980.

Since the 1980s there has been an accelerating change in the focus of production. A large proportion of the output of The Royal Mint now consists of commemorative coins and medals struck to mark significant events and anniversaries. It has diversified into new areas such as bullion and gifting, with the site becoming a visitor attraction in 2016 after the opening of The Royal Mint Experience.

When you buy coins and bars from The Royal Mint, you are purchasing from one of the oldest, most trusted organisations in the world. The weight and purity of your silver bullion coins are determined by an Act of Parliament and the King’s Assay. The King’s Assay Master role was founded in the twelfth century and resides at The Royal Mint.

Today, the task of testing the metallic composition of the coins includes the most modern assay techniques, and is independently verified each year in one of the oldest known quality assurance processes known as The Trial of the Pyx. This is a judicial ceremony that dates back to the thirteenth century, and takes place annually at the Hall of the Worshipful Company of Goldsmiths in London. Throughout the year, coins are randomly selected from every batch of each denomination struck, sealed in bags containing 50 coins each, and locked away in the Pyx boxes for testing at the Trial. They are tested against Trial Plates held by the UK National Measurement Office. A jury elected from members of the Goldsmiths’ Company and at least six assayers from the Worshipful Company of Goldsmiths confirm that the coins are within the statutory limits for metallic composition, weight and size.