For more than 1,100 years, The Royal Mint has been a place of innovation. As well as making beautiful coins, we pioneer new ways of working while honouring the ethos and skills passed down through the centuries.

Through times of technological and social change, our flagship Britannia coin stands as a symbol of progress. Reflecting traditional values while becoming an icon for modern times, our Britannia coin has recently redefined security for the twenty-first century. At the heart of this reinvention are those who work at The Royal Mint striving to make innovation happen.

The Britannia 2022 design is the work of Dan Thorne, one of the youngest designers in our Product Design team. Since 2016, the department has been modernised and, in this time, coin design has been somewhat revolutionised, with The Royal Mint leading the way.

“All coin designs were once worked in plaster but now The Royal Mint’s product designers have almost wholly transferred to digital design. I think laser cutting has been one of the greatest changes for us. It gives a 4K resolution, whereas plaster can only retain so much information.

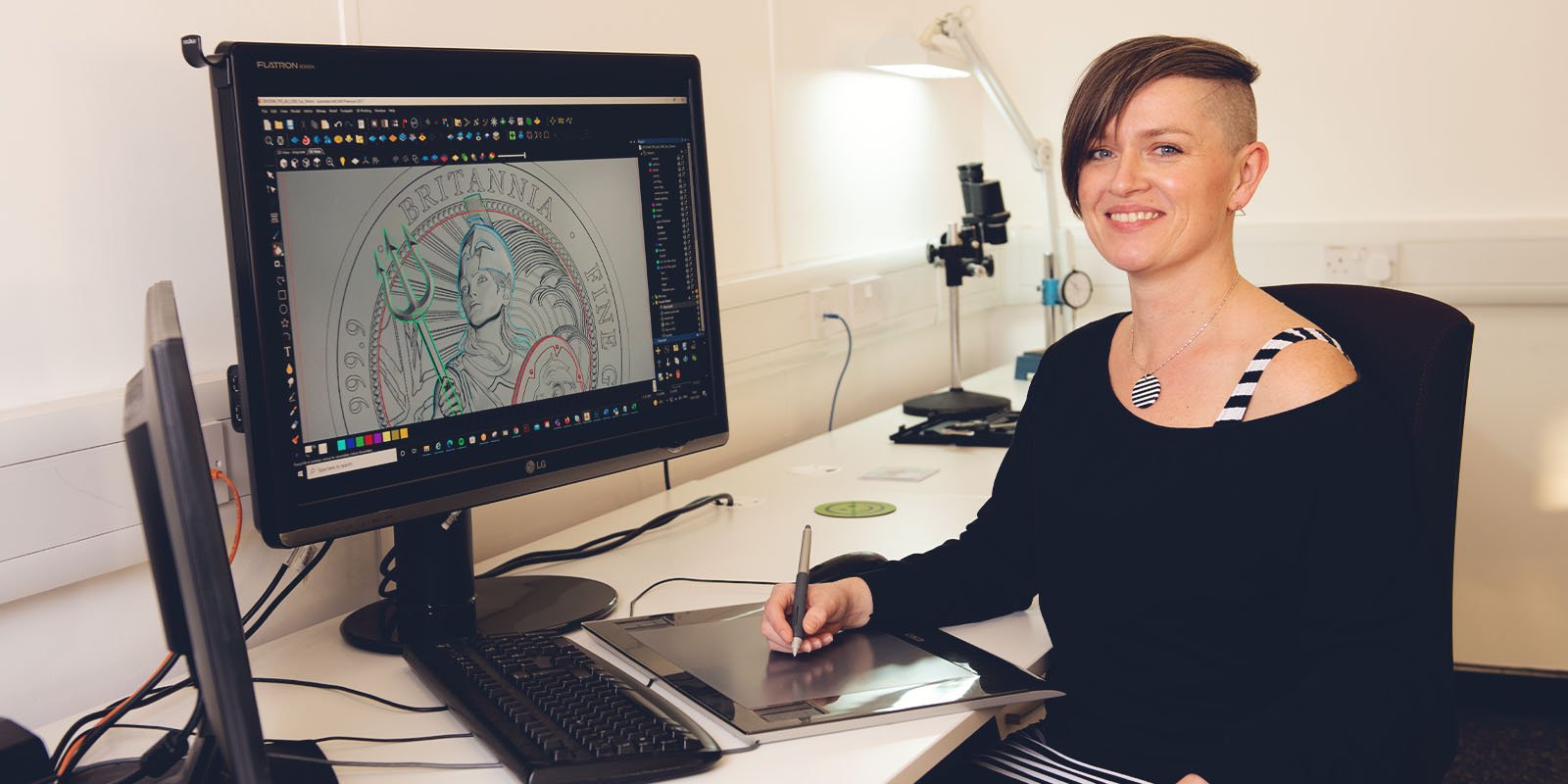

“The majority of tools are cut on the laser to capture the details. We still use plaster models from some of the external designers but I’d say 99% of our work is now digitally created. The designers use a digital programme called Zbrush, which is always updating itself and is a great tool.”

Lee R. Jones, Product Design Lead

As Product Design Lead, Lee has also transformed the team in other ways, ensuring that young designers – like Dan – are nurtured, which has proved particularly important during the COVID-19 pandemic.

“In 2016, I divided the department into two teams, the Technical team and the Concept and Model team. I also set up a new structure of having peer group reviews every day, where the teams can share their work.

“The technology of Microsoft Teams, which enables us to communicate remotely, has been a real strength through the pandemic. One downside has been that we don’t see each other on a day-to-day basis but, with Teams, we can see on the screen what everyone is working on and offer advice and support. Working from home has also provided quiet space and time to focus.”

Lee R. Jones, Product Design Lead

Dan Thorne works in the Concept and Model team and passes his digital models to a member of the Technical team, where the design is refined to create the best coin possible. For this Britannia design, he worked with Kerry Davies, who started at The Royal Mint as an engraver in 2004.

“The job has changed more than I can say! When I applied, the job advertised was for a fine artist. I’m not a fine artist – I did 3D design – but I used to do a lot of mould making and, back then, about 90% of the models were in plaster. We would have one model that would have to be fit for purpose for every size. Now we edit the model at every size, working from Dan’s master digital model. Britannia is one of the most challenging coins we make, as there are so many different sized coins in the range; they should look strong at every size and pose no issue to production.

“My job is to make Britannia the best she can be visually and in production; Dan’s focus is on getting the best design and model. My satisfaction comes when my edit works on a struck coin.”

Kerry Davies, Product Designer

Kerry admits that the Britannia 2022 coin has been rewarding to work on.

“I’m emotionally engaged in this one, as it’s Dan’s first Britannia range. Our young designers, including Dan and Ffion Gwillim, had not been working here very long when we went into lockdown, but through the daily meetings we try to make sure they are supported.

“When I joined The Royal Mint, I really learned by going around the factory and asking questions. I’m inquisitive and I probably challenged why we did things in a certain way, to understand and to develop myself. I had a mentor in a designer called Bob Evans, who was here for about 40 years. He was a traditional engraver who adapted to new methods of working and he knew such a lot.”

Kerry Davies, Product Designer

MEET DESIGNER SANDRA DEIANA

Find out more

MADE FOR GENERATIONS

Find out more

BRITANNIA – THE ICON ON THE COIN

Find out more

BEHIND THE DESIGN WITH DAN THORNE

Find out more